The Black Sheep of the Wool Industy

Since the middle of the past century, when synthetic fibres began their rise, wool has steadily lost importance in the textile sector and is now a marginal fibre on the market. Large amounts of raw wool which used to be a source of income for sheep farmers have turned into waste that is either burned or ends up in landfills. With increasing interest in the sustainable use of natural resources, wool – especially of supposedly lesser quality – should be re-considered as an underrated and underused renewable resource, worthy of better exploration. This project investigates how to use this undervalued European wool, by analysing the agricultural context, the textile industry, the unique properties of sheep wool as well as new textile processing techniques.

There are more than 1,000 sheep breeds in the world, producing fibres of different colours, lengths, and textures. Merino sheep have very fine fibres, which produce fabrics inherently softer than those made from other sheep’s wool. Additionally, most of the wool used in the textile industry is imported from Australia, New Zealand and South Africa. While the value of Merino wool has gone up, the value of wool grown in Europe has gone down. This is because, in Europe, sheep are mainly kept for their meat, milk and the maintenance of landscapes, not their wool. Since different breeds of sheep are more suitable for these purposes, the produced wool varies from very short to long and curly fibres in all sorts of colours. Sadly, since this wool is not reaching the high demands of the textile industry, it is underused, undervalued, and underpriced, despite having almost the same physical and chemical properties as Merino wool.

![]()

![]()

During the project, several wool collection sites were visited organized by SwissWool↗ to better understand the current situation of European wool, the logistics as well as the current processing.

![]()

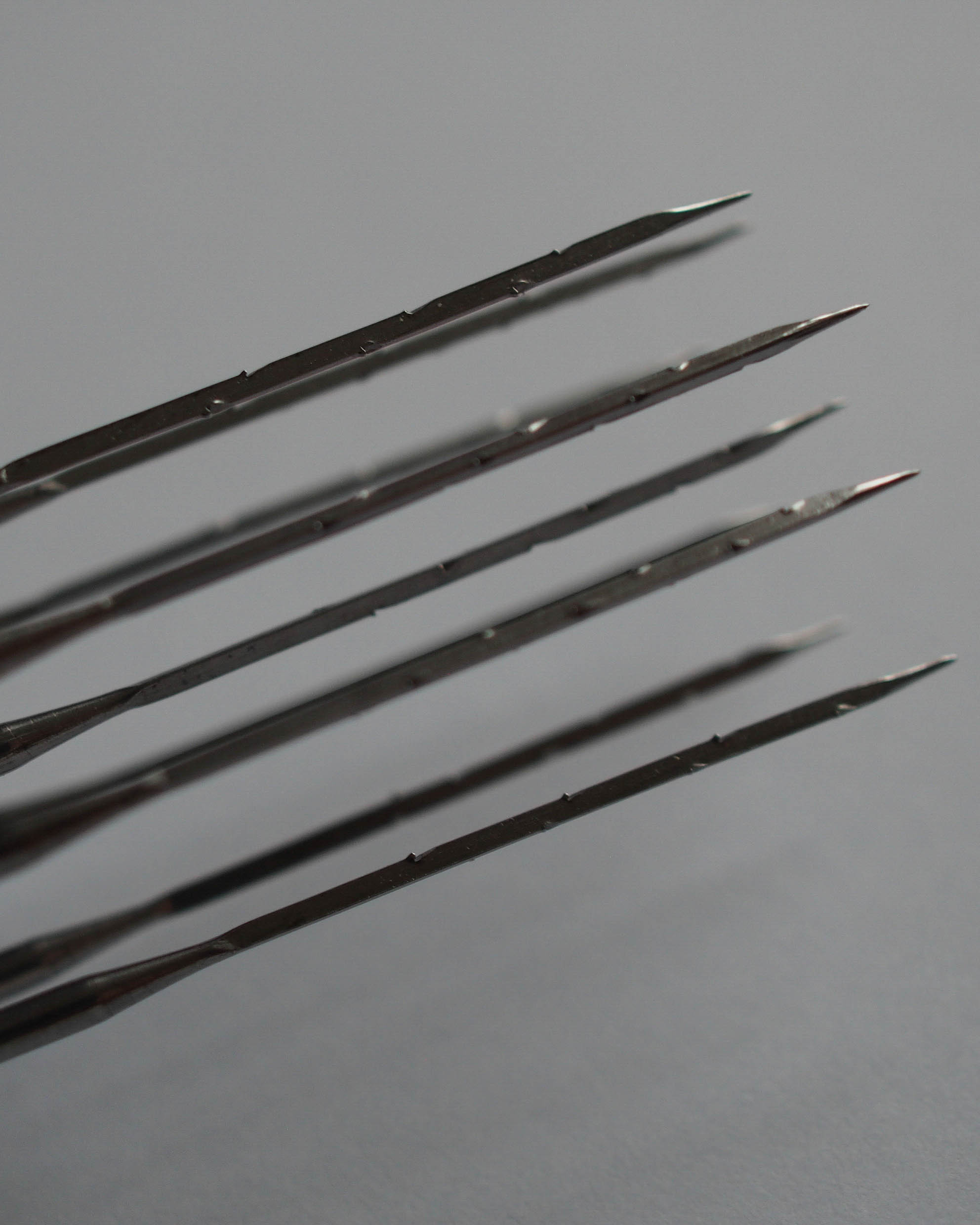

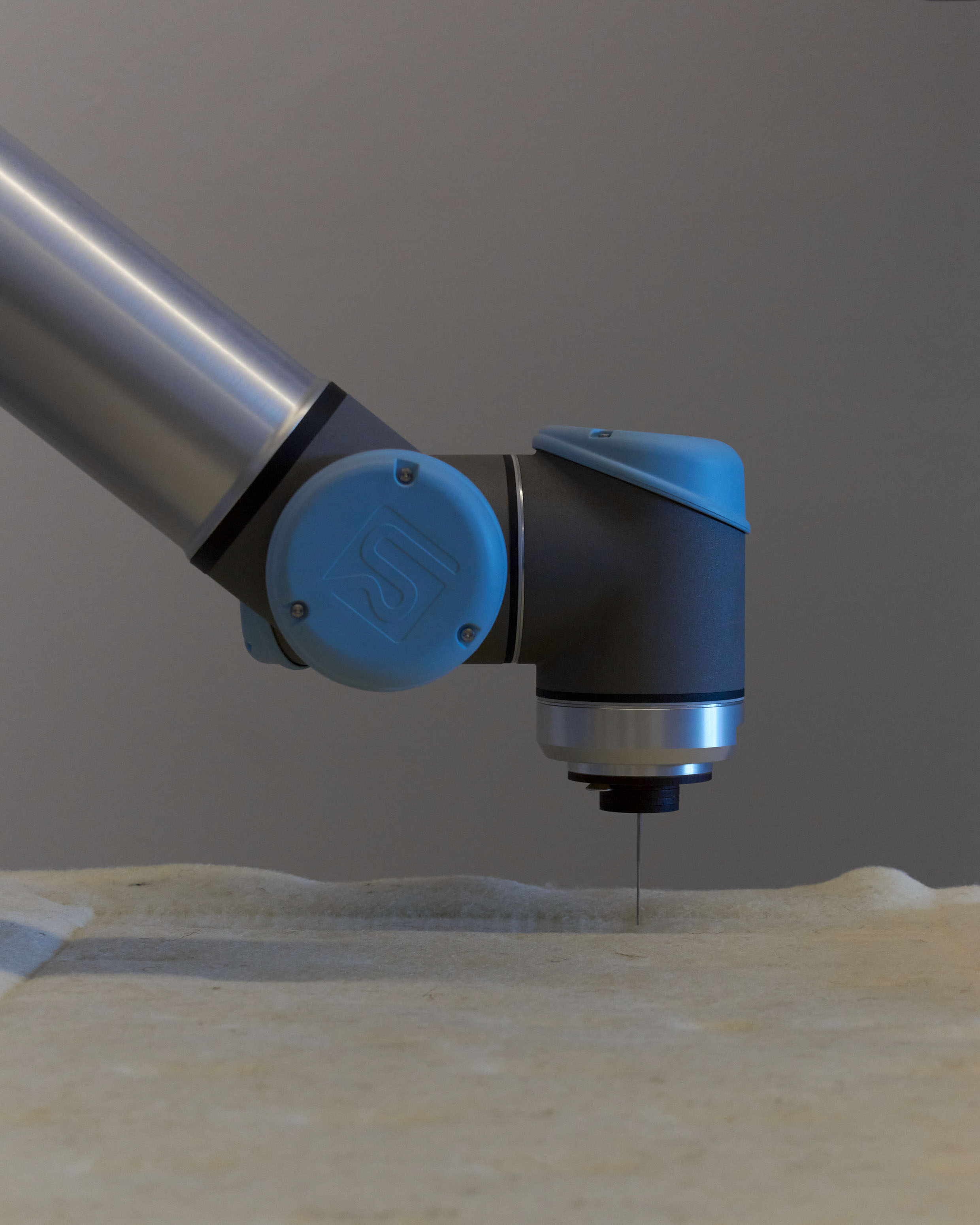

Since fibre production is the highest impact area of fashion for many reasons, a shift towards non-woven fabrics seems to be more promising. The original non-woven is wool felt, made since prehistoric times by applying heat and friction to wool fibres to mat them together – microscopic scales on the fibre interlock and hold the fibres in place. The project explores the technique of robotic needle felting. With this method, felting needles are used, which are equipped with little hooks, felting the fibres together. Using this principle, textiles are made directly from fibres, not yarns. This saves numerous production steps, leading to lower energy consumption and higher traceability.

![]()

![]()

![]()

The research is resulting in a jacket out of 100% European sheep wool, highlighting the unique benefits of the fibre – like insulating properties, breathability, anti-static and self-cleaning – by using the technique of robotic needle felting. In this way, European sheep wool is turned from a burden into a valued raw material.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Contributors

CODING ASSISTANCE AATB↗

TEXTILE Doppelhaus↗

WOOL SwissWool↗

PHOTO/VIDEO Su Yang↗

Awards

Eyes on Talents Winner↗, 2022

Publications

Novembre Global↗

Since the middle of the past century, when synthetic fibres began their rise, wool has steadily lost importance in the textile sector and is now a marginal fibre on the market. Large amounts of raw wool which used to be a source of income for sheep farmers have turned into waste that is either burned or ends up in landfills. With increasing interest in the sustainable use of natural resources, wool – especially of supposedly lesser quality – should be re-considered as an underrated and underused renewable resource, worthy of better exploration. This project investigates how to use this undervalued European wool, by analysing the agricultural context, the textile industry, the unique properties of sheep wool as well as new textile processing techniques.

There are more than 1,000 sheep breeds in the world, producing fibres of different colours, lengths, and textures. Merino sheep have very fine fibres, which produce fabrics inherently softer than those made from other sheep’s wool. Additionally, most of the wool used in the textile industry is imported from Australia, New Zealand and South Africa. While the value of Merino wool has gone up, the value of wool grown in Europe has gone down. This is because, in Europe, sheep are mainly kept for their meat, milk and the maintenance of landscapes, not their wool. Since different breeds of sheep are more suitable for these purposes, the produced wool varies from very short to long and curly fibres in all sorts of colours. Sadly, since this wool is not reaching the high demands of the textile industry, it is underused, undervalued, and underpriced, despite having almost the same physical and chemical properties as Merino wool.

During the project, several wool collection sites were visited organized by SwissWool↗ to better understand the current situation of European wool, the logistics as well as the current processing.

Since fibre production is the highest impact area of fashion for many reasons, a shift towards non-woven fabrics seems to be more promising. The original non-woven is wool felt, made since prehistoric times by applying heat and friction to wool fibres to mat them together – microscopic scales on the fibre interlock and hold the fibres in place. The project explores the technique of robotic needle felting. With this method, felting needles are used, which are equipped with little hooks, felting the fibres together. Using this principle, textiles are made directly from fibres, not yarns. This saves numerous production steps, leading to lower energy consumption and higher traceability.

The research is resulting in a jacket out of 100% European sheep wool, highlighting the unique benefits of the fibre – like insulating properties, breathability, anti-static and self-cleaning – by using the technique of robotic needle felting. In this way, European sheep wool is turned from a burden into a valued raw material.

Contributors

CODING ASSISTANCE AATB↗

TEXTILE Doppelhaus↗

WOOL SwissWool↗

PHOTO/VIDEO Su Yang↗

Awards

Eyes on Talents Winner↗, 2022

Publications

Novembre Global↗